|

|||||||

| المنتدى التعليمى والمكتبة الفنية كتب وشروحات ومقالات تعليمية عن كل فروع هندسة وميكانيكا السيارات |

|

|

|

أدوات الموضوع |

|

|||||||

| المنتدى التعليمى والمكتبة الفنية كتب وشروحات ومقالات تعليمية عن كل فروع هندسة وميكانيكا السيارات |

|

|

|

أدوات الموضوع |

|

#1

|

|||

|

|||

|

Variable Compression Ratio engine ( VCR )

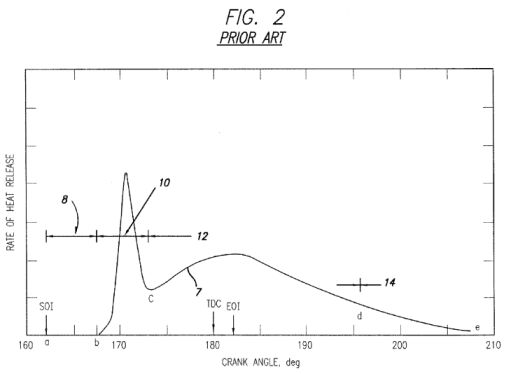

الرابط http://api.viglink.com/api/click?format=go&key=6afc7 8eea2339e9c047ab6748b0d37 e7&loc=http%3A%2F%2Fwww.p hysicsforums.com%2Fshowth read.php%3Ft%3D341640&v=1 &libid=1342277629533&out= http%3A%2F%2Fwww.pattakon .com%2F&title=Variable%20 Compression%20Ratio%20eng ine%20(%20VCR%20)&txt=htt p%3A%2F%2Fwww.pattakon.co m&jsonp=vglnk_jsonp_13422 778698281 Take a look at http://www.pattakon.com/ for some VCR designs, like the pat-head:  or like the patcrank:  or like the patrack:  The http://www.pattakon.com/pattakonKeyAdv.htm is explanatory. The basics of V8 patcrank VCR are shown in this simple gif animation:  The main crankshaft (red) is conventionally supported on the crankcase and drives conventionally the flywheel and the gearbox. Saab variable compression engine. With a mounted supercharger        Because cylinder bore diameter, piston stroke length and combustion chamber volume are almost always constant, the compression ratio for a given engine is almost always constant, until engine wear takes its toll. One exception is the experimental Saab Variable Compression engine (SVC). This engine, designed by Saab Automobile, uses a technique that dynamically alters the volume of the combustion chamber (Vc), which, via the above equation, changes the compression ratio (CR). To alter Vc, the SVC 'lowers' the cylinder head closer to the crankshaft. It does this by replacing the typical one-part engine block with a two-part unit, with the crankshaft in the lower block and the cylinders in the upper portion. The two blocks are hinged together at one side (imagine a book, lying flat on a table, with the front cover held an inch or so above the title page). By pivoting the upper block around the hinge point, the Vc (imagine the air between the front cover of the book and the title page) can be modified. In practice, the SVC adjusts the upper block through a small range of motion, using a hydraulic actuator. BorgWarner's Variable Cam Timing Technology Saves Five Percent of Fuel 2009-02-24 - BorgWarner's Cam Torque Actuated (CTA) Variable Cam Timing (VCT) technology gets its latest application on the Jaguar AJ-V8 Gen III five litre V8 engine, which will power the 2010 model year Jaguar XK/XKR and XF/XFR. Conventional cam phasers generally use engine oil pressure to phase the camshaft. CTA technology, however, performs like a hydraulic ratchet to harness existing torsional energy in the valve train to phase the camshaft. "BorgWarner's CTA technology optimises variable cam timing, making it more efficient at all engine speeds, with faster response than traditional hydraulic oil-actuated VCT systems," says Alfred Weber, president and general manager, BorgWarner Morse TEC. Compared with traditional cam phasers, CTA technology operates more quickly and at a wider range of temperatures and at engine speeds down to 500 rpm, the company says, allowing an average five percent improvement in fuel economy, reduced emissions and increased horsepower. The system is also less likely to suffer oil aeration due to low oil consumption averaging only 0.2 litres per minute to 0.4 litres per minute. CTA technology will work with both overhead-cam and overhead-valve engines. Also known as the CTA Camshaft Phasing System, the technology was first introduced in the new generation Duratec three litre V6 for the 2009 Ford Escape, and will be used in the 2010 Ford Fusion and Mercury Milan. BorgWarner says it is developing the system for five additional customers worldwide. Nissan Variable Compression Engine FEV Variable Compression Ratio Rod  transonic ignition engine The novel SC injection systems, which Rocke calls “almost drop-in” units, include “a GDI-type,” common-rail system that incorporates a metal-oxide catalyst that breaks fuel molecules down into simpler hydrocarbon chains, and a precision, high-speed (piezoelectric) injector whose resistance-heated pin places the fuel in a supercritical state as it enters the cylinder. Company engineers have doubled the fuel efficiency numbers in dynamometer tests of gas engines fitted with the company’s prototype SC fuel-injection systems, Rocke said. A modified gasoline engine installed in a 3200-lb (1451-kg) test vehicle, for example, is getting 98 mpg (41.6 km/L) when running at a steady 50 mph (80 km/h) in the lab. The 48-employee firm is finalizing a development engine for a test fleet of from 10 to 100 vehicles, while trying to find a partner with whom to manufacture and market TSCi systems by 2014. “A supercritical fluid is basically a fourth state of matter that’s part way between a gas and liquid,” said Michael Frick, Vice President for Engineering. A substance goes supercritical when it is heated beyond a certain thermodynamic critical point so that it refuses to liquefy no matter how much pressure is applied. SC fluids have unique properties. For a start, their density is midway between those of a liquid and gas, about half to 60% that of the liquid. On the other hand, they also feature the molecular diffusion rates of a gas and so can dissolve substances that are usually tough to place in solution. To minimize friction losses, the Transonic engineers have steadily reduced the compression of their test engines to between 20:1 and 16:1, with the possibility of 13:1 for gasoline engines. Patents US2010024776 PIEZOELECTRIC FUEL INJECTOR HAVING A TEMPERATURE COMPENSATING UNIT Inventor: FRICK MICHAEL J [US] ; CHEIKY MICHAEL Abstract-- The present invention provides a fuel injector, comprising a housing having a sealable injector seat; a fuel injector pin disposed within the housing proximate to the injector seat such that the injector seat may be sealed and unsealed by displacing the fuel injector pin; a resilient element biasing the fuel injector pin in an unsealed direction; a piezoelectric actuator disposed within the housing proximal to the fuel injector pin configured to actuate to force the injector pin towards the injector seat to seal the injector seat; and a thermal compensating unit disposed within the housing proximal to the actuator and configured to compensate for thermal expansion or contraction of a component of the fuel injector.          USP 7657363 USP 7444230 Fuel injector having algorithm controlled look-ahead timing for injector Abstract -- An injector-ignition fuel injection system for an internal combustion engine, comprising an ECU controlling a heated catalyzed fuel injector for heating and catalyzing a next fuel charge, wherein the ECU uses a one firing cycle look-ahead algorithm for controlling...            WO2007123671 HEATED CATALYZED FUEL INJECTOR FOR INJECTION IGNITION ENGINES Inventor: CHEIKY MICHAEL the promising qualities of the Grail Engine as explained in an online how to article (how does the grail engine work). In fact, I was so taken by some of the concepts of this engine that I went on to read more about it on the grail engine company website. This article represents a collection of my thoughts and reactions as I read about the Grail Engine with a sprinkle of my life long fascination with the combustion engine for good measure - the aim here is to provide a non-marketing focused interpretation of this technology.  HCCI provides up to a 15% fuel savings over traditional spark plug ignition while meeting current emission standards. This technology involves compressing fuel air mixture to the point it combusts. HCCI closely resembles the ignition process that occurs in diesel engines. The Grail Engine uses a variant of this where instead of compressing to the point of ignition, it compresses "nearly" to the point of ignition and then fires  three spark plugs to more completely burn the compressed fuel air mixture. three spark plugs to more completely burn the compressed fuel air mixture. Achilles Heel of the Grail Engine  What I believe is the Achilles Heel of the Grail Engine is its innovative use of a valve atop the piston (this is NOT common among modern day engines) which is uniquely shown via an animation provided by the company. In this animation, the valve atop the piston opens at the start of the upward compression (pre-combustion) stroke to allow fresh air previously compressed What I believe is the Achilles Heel of the Grail Engine is its innovative use of a valve atop the piston (this is NOT common among modern day engines) which is uniquely shown via an animation provided by the company. In this animation, the valve atop the piston opens at the start of the upward compression (pre-combustion) stroke to allow fresh air previously compressed  (pre-heated) below the cylinder (during the previous power stroke) to enter the combustion chamber to replace the exhaust which is vented out the valve atop of the cylinder head that is opened and closed just prior to the piston valve opening. (pre-heated) below the cylinder (during the previous power stroke) to enter the combustion chamber to replace the exhaust which is vented out the valve atop of the cylinder head that is opened and closed just prior to the piston valve opening.The top of the piston is typically a combustion battleground, where unused combustibles (artifacts) wind up and adhere to its surface (see example figures of a traditional piston after extensive use). While the Grail Engine probably does perform quite well when everything is new (most engines do), the Grail Engine would exceedingly become sensitive to the natural build up of combustible artifacts that will not only severely impact its efficiency, but also can lead to malfunction (such as blow-by which is caused when a combustion chamber is improperly sealed by its rings and the resulting combustion is able to forcibly enter the crank case) and or a much shortened life.     TSCiTM Technology      The Transonic Combustion system (TSCiTM) is a new combustion process for the gasoline internal combustion engine. The TSCiTM combustion process utilizes direct injection of fuel into the cylinder as a supercritical fluid based on the patented concept of injection-ignition. Supercritical fuel promotes rapid mixing with the contents of the cylinder which, after a short delay, results in spontaneous ignition at multiple locations. Multiple ignition sites and rapid combustion combine to result in optimum heat release and high cycle efficiency. Other advantages are the elimination of droplet burning and increased combustion stability that results from multiple ignition sources. The Transonic Combustion system (TSCiTM) is a new combustion process for the gasoline internal combustion engine. The TSCiTM combustion process utilizes direct injection of fuel into the cylinder as a supercritical fluid based on the patented concept of injection-ignition. Supercritical fuel promotes rapid mixing with the contents of the cylinder which, after a short delay, results in spontaneous ignition at multiple locations. Multiple ignition sites and rapid combustion combine to result in optimum heat release and high cycle efficiency. Other advantages are the elimination of droplet burning and increased combustion stability that results from multiple ignition sources.TSCiTM brings together the injection and ignition processes to become Injection-Ignition. The characteristics of TSCiTM address all of the issues identified above as limiting the efficiency of the gasoline engine; it is capable of operating over a wide range of air/fuel ratios and so does not require a throttle for load control. TSCiTM has inherently short combustion delay and rapid combustion that result in heat release phasing for optimal efficiency. TSCiTM can be operated at an optimal compression ratio since it is not dependent on high octane gasoline. The ignition mechanism renders the combustion system fuel neutral in the sense it is not reliant on either Octane or Cetane values. A characteristic of the TSCiTM combustion process is that injection of the fuel is delayed to the extent that the heat release predominantly takes place after TDC of the engine power stroke. In order to achieve this, the combustion process must have rapid air-fuel mixing, followed by a short delay period and combustion. Such characteristics can be achieved by injecting the fuel in the form of a supercritical fluid. A supercritical fluid is any substance at a temperature and pressure above its critical point; it is not a solid, liquid or a gas. Generally supercritical fluids have properties between those of a gas and a liquid. Supercritical fluids also have other unique properties such as having no surface tension, the ability to solvate other liquids and solids and the formation of small particles with a narrow size distribution during a phase change to liquid. Supercritical fluids possess rapid mass transfer properties with diffusion coefficients more than ten times that of a liquid near the critical point. The density ranges between one third and two thirds of that of the corresponding fluid and varies significantly with temperature and pressure.  EPA Cycle Testing of Transonic's Technology Demonstrator Vehicle TSCiTM R&D Prototype Injectors The potential of the technology is to provide real world fuel consumption reductions of 25% to 30% in gasoline fueled passenger cars with corresponding reductions of greenhouses gases. Transonic Combustion's TSCiTM is an innovative fuel injection system comprised of fuel injectors, fuel heaters, an electronic control unit, and a high-efficiency fuel pump. The technology is optimized for gasoline engines. The TSCiTM system has broad US patent coverage on the use of a supercritical fluid in a fuel injection system. Nine US patents have been issued. More than ten US patents are pending. Additionally, foreign patent protection is being pursued, with two patents issued in China and over 10 International patents are in process. The specific details of TSCiTM patented technology are highly proprietary and reviewable only under Non Disclosure Agreement. الرابط http://www.google.com.eg/url?sa=t&rct=j&q=tsci%20e ngine&source=web&cd=1&ved =0CFMQFjAA&url=http%3A%2F %2Fwww.tscombustion.com%2 Ftscitechnology.html&ei=O pQBUKO_BNDXsgaJ-b3cBg&usg=AFQjCNFN4hy2UBo 7ZIFkJLegF5dSmXm_MA |

|

#2

|

||||

|

||||

|

موضوع متميز من عضو مبدع

تسلم ايدك يا باشا و رمضان كريم |

|

#3

|

||||

|

||||

|

الموضوع كبير بس رااااااااااائع ومستني مداخلات الاعضاء الخبره عشان اجمع الموضوع بشكل كويس

... ...

__________________

وأتت ملائكة النعيم كما روت* روحي بطون أكفها خضراء* صعدت بروحك والعبير يحفها* والنور ترسم دربه الأنواء* شرقت حشاشات النحيب وأينعت* وشوى الأنين قلوبنا فتفطرت*خلف الجفون دموعنا الخرساء* أكبادنا فبكاؤنا إيماء*

|

|

#4

|

||||

|

||||

واضح يا أدماير ان الشركات دى مش بتهظر للاسف يا كبييير لسه قدمنا كتييييييييير اوووووى    :p ty: :p ty:

__________________

دا لينك اولتراس فيات 132 دا لينك صفحتى على الفيس بوك ![Fun 36 3 9[1]](images/smilies/fun_36_3_9[1].gif) ![Fun 36 3 9[1]](images/smilies/fun_36_3_9[1].gif) ![Fun 36 3 9[1]](images/smilies/fun_36_3_9[1].gif) |

|

#5

|

|||

|

|||

|

الله اكرم

:T HUMB_~112: :T HUMB_~112:

|

|

| الكلمات الدليلية |

| piezoelectric, transonic |

|

|