The

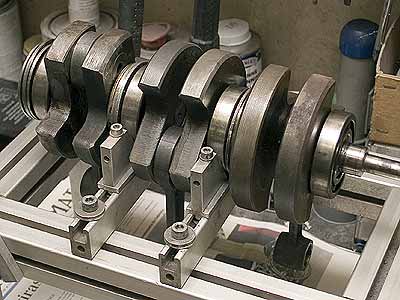

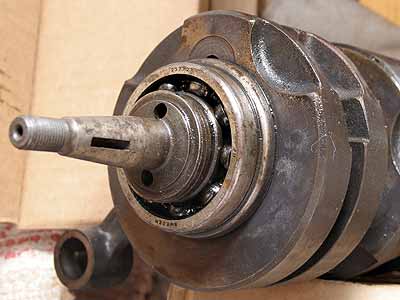

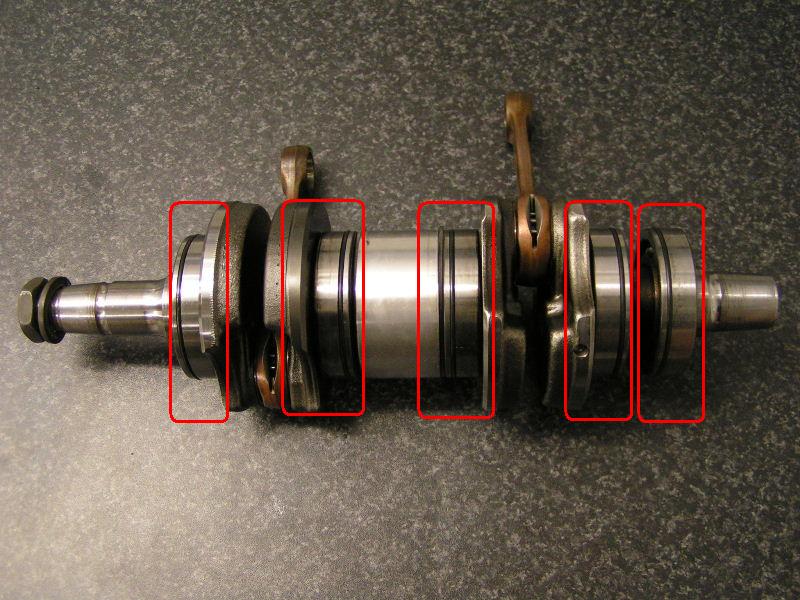

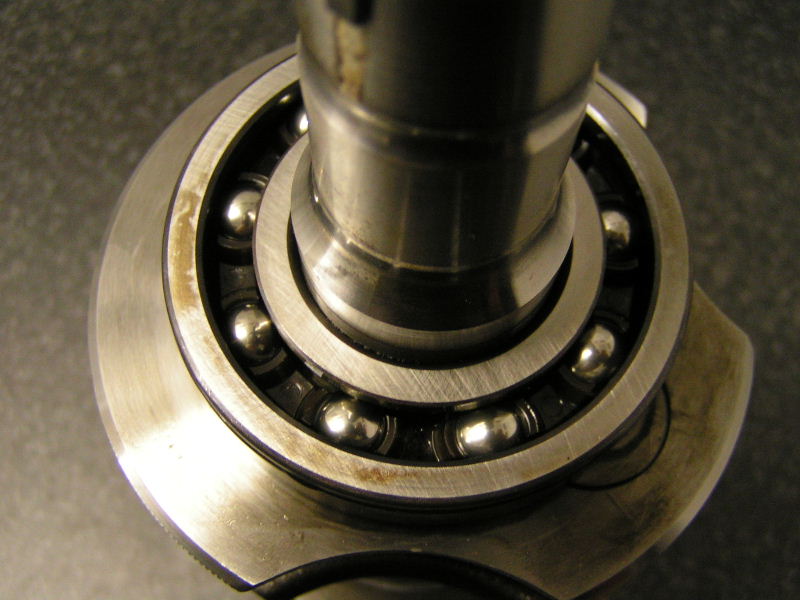

crankshaft main

bearings are regular

ball bearings

well…

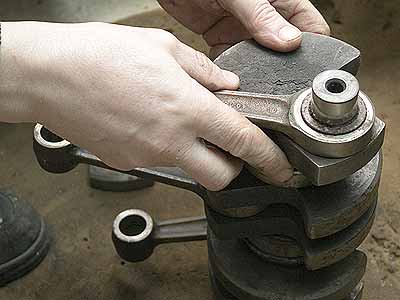

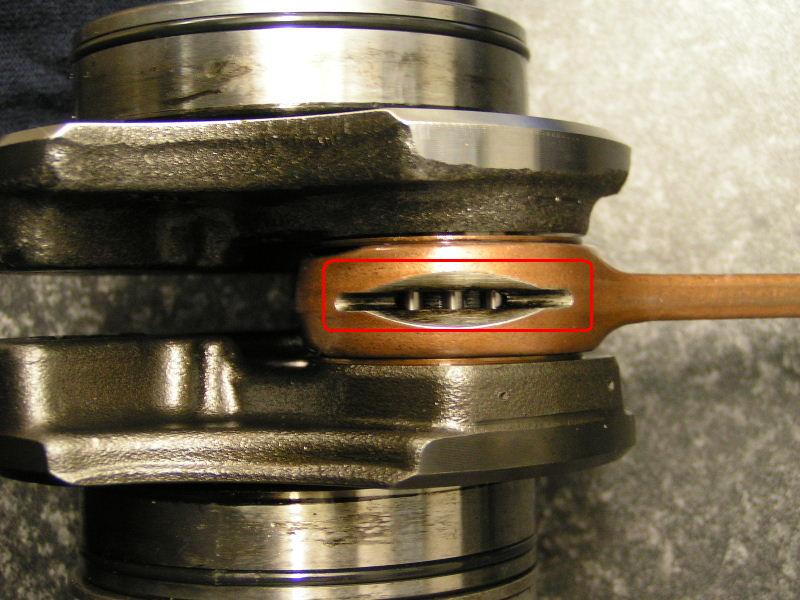

The crankshaft needs to be completely dismantled in a press to change the bearings. Actually you cannot see the connection rod bearings or the connection rod pin condition before you dismantle the shaft. The new bearings (and new pins if necessary) are also pushed to correct place in a press. After that the whole axle is put together again in a press.

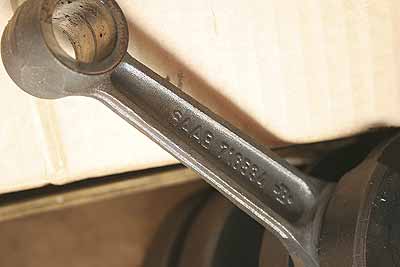

This connection rod pin is clearly worn and needs to be replaced:

Above: The small picture shows the original roller bearing (with cast aluminium body) which were not very reliable on the long run. These are no-longer availlable, which requires that different type of bearing is used:

Main picture, from left, is the new connection rod pin (the center has bigger diameter to accommodate the new bearing). At center is the new bearings inner race and on the right the new needle-type roller bearing. This bearing has bigger diameter on the outside than the old one, so the connection rod big end needs some grinding.

The crankshaft main bearings are regular ball bearings and are readily availlable.

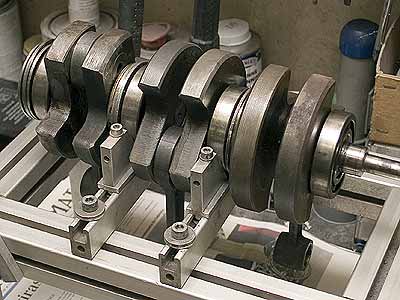

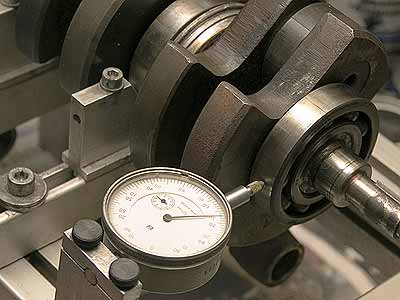

Pictures above: When the axle has been put together, it needs to be straightened (trued?). Straightening is a process of measuring the axle in a jig and hitting it with a hammer to eliminate the “wobble”. The factory tolerance for straightness measured as above, is less than 5/100 millimeter.

Here’s Lasse demonstrating the surgically precise hammer blows!

Don’t try this at home!

Really, this is best left to the experts.

And remember:

Never drop the crankshaft! The odds are, it will not be straight afterwards…

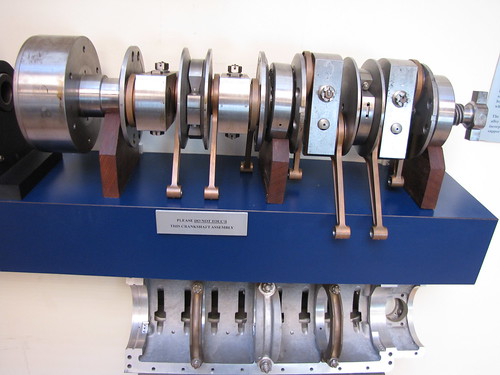

A few pics of the Saab Sport crankshaft I recently managed to get hold of:

On the left the “counterweight” or limput (“loafs” as we call them) of the sport-type and on the right the regular one. The sport axle has more mass than the regular one and the fully round “loafs” ensure better balance of the whole crankshaft enabling higher revolutions.

The bigger “counterweights” also take up more space in the crankcase, which results in higher pressure in the cylinder (more mixture). This gives you more power.

The Sport crankshaft also has better crankcase chamber-to-chamber sealing (see the sealing rings on both sides of the main bearings.

Above the full axle, very easy to identify by the fully round “loafs”.

Needle

Roller Cage Assemblies for

Connecting Rod

رولمان بلى بديل جلب البنوز والسبايك !!

رولمان بلى بديل جلب البنوز والسبايك !!

NTN Develops an Environmental Friendly Low Friction Needle Roller Bearing For Automotive Engines

Improves Automotive Fuel Efficiency by 3% and Makes Oil Pumps

and Starters More Compact and Light Weight

NTN Develops an Environmental Friendly Low Friction Needle Roller Bearing For Automotive Engines

Improves Automotive Fuel Efficiency by 3% and Makes Oil Pumps

and Starters More Compact and Light Weight

NTN Corporation (NTN) has developed Low Friction Needle Roller Bearings for automotive crankshaft and camshaft support applications. These bearings reduce torque considerably when compared to conventional plain bearings.

In recent years, engine oil viscosity has become lower to help reduce friction and improve fuel efficiency. In light of this, the use of rolling bearings instead of plain bearings has been considered to help reduce friction in the engine shaft support applications.

However, it is impossible to mount normal rolling bearings in these applications. Because of the crank arm and cam on the crankshaft and camshaft, only split type bearings with small cross-sectional heights will work. There have been no rolling bearings available to meet these needs. For this application, until now, either split type plain bearings have been used or the aluminum housing and shaft were placed directly in sliding contact.

In response to this,

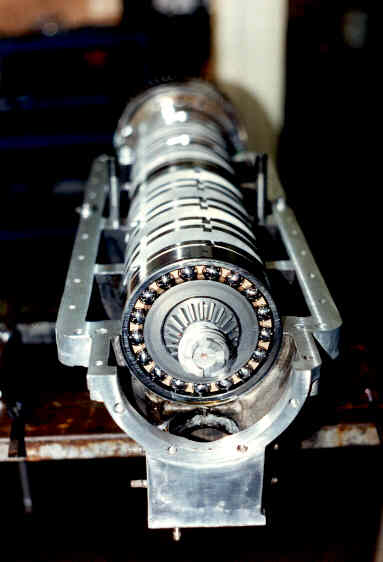

NTN has developed a split type rolling bearing for these two applications. NTN's newly developed Low Friction Needle Roller Bearings have a small cross-sectional height and can be easily mounted on the crankshaft and camshaft, contributing to increased automotive fuel economy and a more compact design.

For crank-shaft support applications:

Both the outer ring and the cage are split into two pieces. NTN's new split technology has made possible a high precision outer ring with a small cross-sectional height of 2mm. NTN's engine bearing technology also improves the cage's anti-seizure property and strength.

For cam-shaft support applications:

The drawn-cup outer ring is split into two pieces and the plastic cage is one piece but cut at one place. The use of a split drawn-cup made it possible to decrease the outer ring cross-sectional

height to 0.6mm, which contributes to space reduction. Also, the outer ring strength was increased by optimizing its configuration using FEM analysis.

[Features: (compared with plain bearings)]

(1)Startup torque reduced by approximately 90%(2)Rotational torque reduced by approximately 50%(3)Increased vehicle fuel efficiency by approximately 3%

(measured by "10.15" gas emission test run mode)(4)Making engine oil-pump and starter more compact and light weight

(VA/VE can be expected)

[Contact]

- Planning and Marketing Department, Automotive Sales Headquarters

Phone: 03-5487-2814

[Photos]

Crankshaft low frinction needle roller bearing

Camshaft low friction needle roller bearing

[Advantages]

[How it Works]

[How it Works]

(1)For crank-shaft support applications: Outer ring sectional height decreased to 2mm by NTN's new production method

to split outer ring ⇒ Contributing to space reduction

Cage anti-seizure property and strength improved by NTN's engine bearing technology (2)For cam-shaft support applications: Outer ring sectional height decreased to 0.6mm

by using press formed drawn-cup outer ring ⇒ Contributing to space reduction

Outer ring strength improved by optimum design using FEM analysis (2)For cam-shaft support applications: Outer ring sectional height decreased to 0.6mm

by using press formed drawn-cup outer ring ⇒ Contributing to space reduction

Outer ring strength improved by optimum design using FEM analysis

[Performance:

(Measured torque value, in comparison with plain bearing)]

·

Startup torque : 90% less·Rotating torque : 50% less

crank and inspected the 5 roller bearings.

·

![36 13 6[1]](images/smilies/36_13_6[1].gif)

![36 13 6[1]](images/smilies/36_13_6[1].gif)

![36 13 6[1]](images/smilies/36_13_6[1].gif)

![36 13 6[1]](images/smilies/36_13_6[1].gif)

![36 13 6[1]](images/smilies/36_13_6[1].gif)

![36 13 6[1]](images/smilies/36_13_6[1].gif)